We cultivate a dynamic team spirit oriented towards innovation and the well-being of patients

As early as 1989, Symbios pioneered the use of medical imaging in combination with 3D simulation software to enable the design of custom orthopedic implants. Symbios continues to exhibit, more than any other medical device company, the same strong software culture that has always been part of the company’s history. Our talented engineers develop and maintain dozens of different in-house software products in parallel, ranging from 3D custom implant design software, to 3D pre-operative planning software, and web-based applications that allow our customers to manage and track orders for custom devices. Get ready to join a stimulating environment that requires an agile development methodology while respecting strict quality standards.

See Available Jobseast

In orthopedics, an efficient and reliable supply chain is essential in providing surgeons with the service they need when they need it. This is even more true for individualized implants: Symbios is committed to delivering its individualized devices within a few weeks, on a just-in-time basis, from order to surgery, which represents a huge industrial challenge. Our logistics staff are committed to getting our products to surgeons in the fastest and most efficient way possible. Areas of activity include supply chain management, manufacturing planning, purchasing and supplier management, business planning and inventory control, as well as customer service to deliver our products to hospitals.

See Available Jobseast

In accordance with our Quality Policy, the quality of our products and patient well-being come first and guide everything we do. The Quality Assurance and Regulatory Affairs staff at Symbios are committed to ensuring that everything we do meets the highest quality standards and complies with an increasingly demanding regulatory environment. Areas of activity include obtaining and maintaining certification of our products for all required geographical areas, maintaining and improving our Quality Management System and its certification, providing state-of-the-art engineering to control our products in production, managing audits of our subcontractors to ensure that they meet our quality standards, post-marketing surveillance, and clinical evaluation of our products to ensure that they safely deliver the expected performance in accordance with their intended use.

See Available Jobseast

Numerous finishing operations are required to ensure that our orthopedic products meet the surface finish specifications defined by our Product Engineering teams. Our finishing specialists use the skills they have acquired over the years to transform machined blanks into high quality mirror polished implants. Areas of activity include manual and automated polishing (smurotropy), sandblasting and bead blasting.

See Available Jobseast

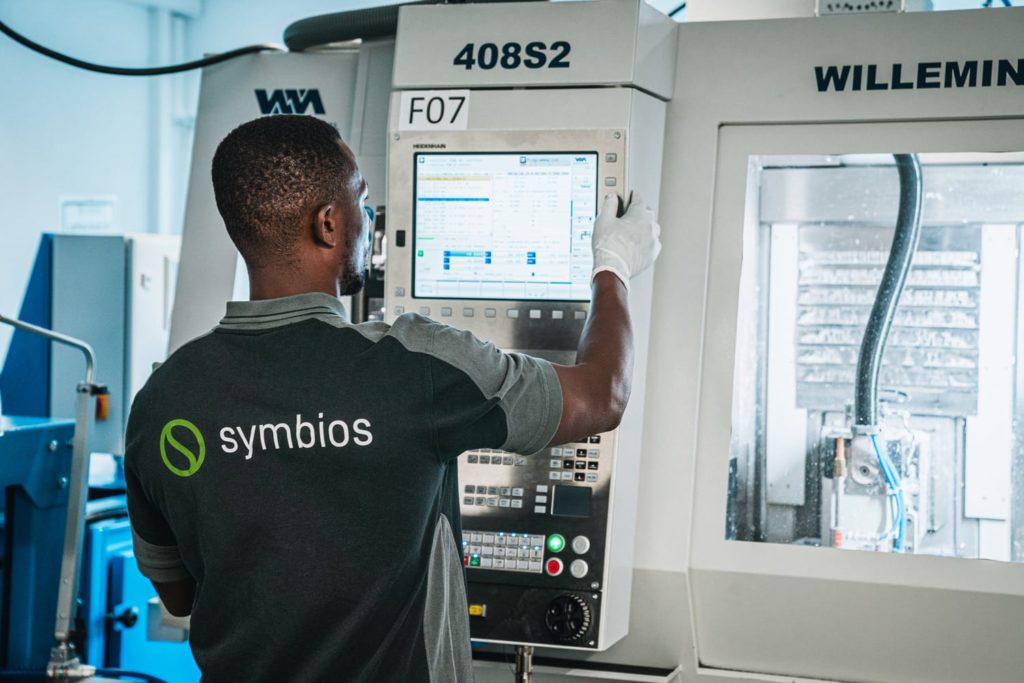

At Symbios, we are proud to contribute to nurturing the strong tradition of Swiss manufacturing that has developed over the centuries in the local watch industry. Our competitiveness is ensured by our qualified staff using modern and highly automated manufacturing technologies. We can also rely on a select group of tooling and mechanical sub-contractors who help us achieve manufacturing excellence. Areas of activity include 5-axis CNC milling (HERMLE, Willemin-Macodel and Mori-Seiki), CNC turning (Mori-Seiki), as well as additive manufacturing and 3D printing (EOS).

See Available Jobseast

At Symbios, we are committed to providing the highest quality orthopedic products. Our employees are all mindful that our products are implanted in patients, and that surgeons’ trust can only be achieved through excellence. Our production quality team is responsible for implementing systematic and rigorous quality controls in production to ensure that every device we bring to market meets this level of excellence. Areas of activity include automated CMM checks, roughness checks, visual inspection, final batch release, incoming inspection and document control.

See Available Jobseast

Working in a clean room environment that meets the strictest standards, our staff ensure the controlled packaging of our implants in accordance with current regulatory requirements. Our implants are then sterilized by gamma or ethylene oxide irradiation before being shipped to hospitals worldwide. Our qualified clean room operators are responsible for this critical operation, which must be performed with rigor to ensure the expected performance of our implants.

See Available Jobseast

At Symbios, sales representatives play a key role in assisting and advising orthopedic surgeons in the use of our products to ensure the highest quality of care for their patients. Orthopedic devices being technically complex products, our talented and highly skilled sales teams work hard to establish and sustain a trusting relationship with surgeons. Areas of activity include local sales representatives in each Symbios subsidiary, key account management, sales management and international business development to build relationships with distributors around the world.

See Available Jobseast

Our Marketing team works directly with orthopedic surgeons and product engineers as products are developed through to their launch in our markets. Areas of activity include Product Management across the entire product lifecycle, as well as marketing communication, management of training programs and events, and the organization of Symbios’ exhibition activities at orthopedic congresses around the world.

See Available Jobseast

To meet the challenges of supplying our implants worldwide, we rely on the dedicated support of our corporate functions based at our headquarters in Switzerland. Our corporate function employees create value for all other Symbios stakeholders who rely on them for their daily work. The business areas include accounting and finance, information systems and technology, legal affairs and human resources.

See Available Jobseast

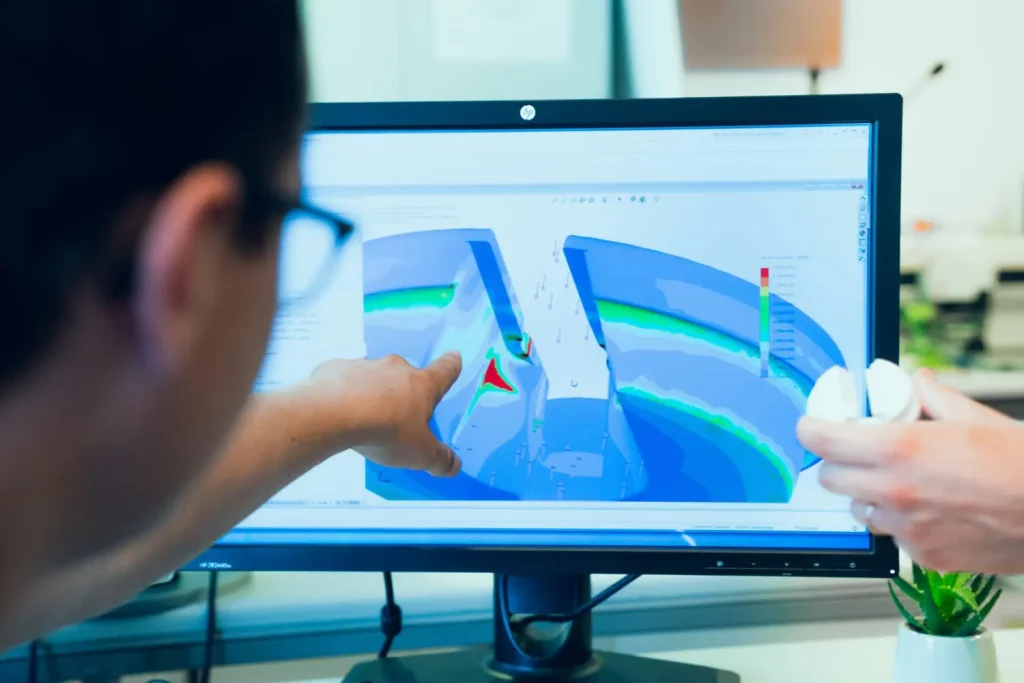

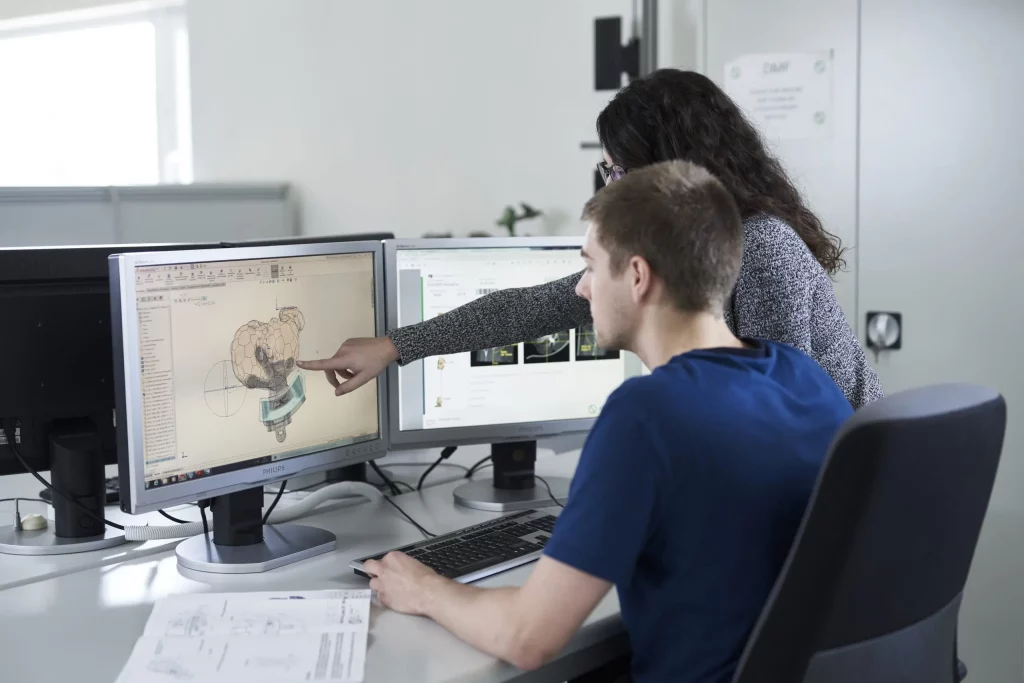

Individualized prostheses are at the center of what we do at Symbios. Our Custom Design team develops individualized hip and knee implants and instruments in collaboration with surgeons from around the world. As a result of this work, we develop a thorough knowledge of hip and knee anatomy and 3D orthopedic surgical planning. Our specialized engineers and technicians analyze and discuss the preoperative planning of each case with surgeons, and are an integral part of the care process with our clients, helping to eliminate pain and restore mobility to thousands of patients each year.

See Available Jobseast

Product design plays a key role for an orthopedic company because even the smallest details can make a huge difference in clinical outcomes. Our Product Engineering team designs innovative products in collaboration with orthopedic surgeons, while always considering patient well-being. Areas of activity include product design and prototyping, CAD drawing, project and supplier management, product validation and testing, technical documentation, manufacturing engineering, machining strategy and programming, process qualification and validation. Our staff must combine creativity with strong engineering skills and agile methodology to ensure short time-to-market cycles, while ensuring compliance with a highly demanding regulatory environment.

See Available Jobseast